Comprehensive technical consulting

At MOVITEC we offer much more than machinery: we provide a specialized consulting service that accompanies our clients in all phases of the process —before, during and after purchase— with the objective of maximizing the performance, efficiency and profitability of their production lines.

Thanks to our engineering and technical consulting team, we work hand in hand with each client to understand their specific needs and offer personalized solutions that make a real difference in their daily operations.

WHAT DOES OUR CONSULTING SERVICE INCLUDE?

- Personalized technical consulting from the first contact.

- Production calculations to properly size the solution.

- Layouts adapted to the reality of your plant.

- Performance improvement of baling systems and end-of-line optimization.

- Specific solutions for picking and logistics processes.

- Reduction of plastic film consumption, without compromising load stability.

- Return on investment (ROI) analysis to make data-based decisions.

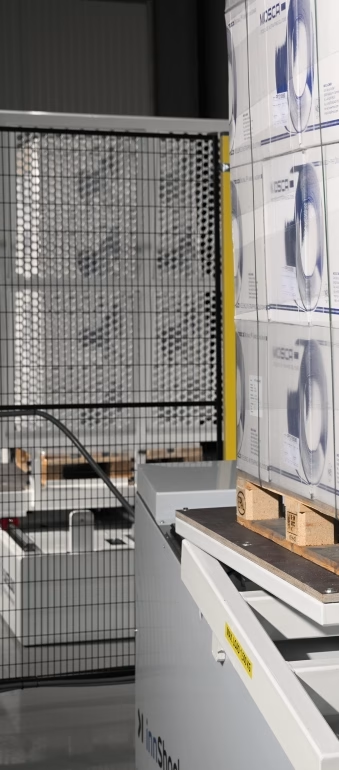

Analyze, test and optimize your load units

Load units are exposed to multiple stresses during transport. Choosing appropriate packaging is fundamental, especially when shipping dangerous goods. If an accident occurs, it can have serious consequences: from material damage to personal injury. As a distributor of the load unit, you may face significant legal responsibilities, as you are responsible for its safety.

To help you choose the right packaging for your transport route, we test the safety of your loads in our TechCenter.. A test at the TechCenter goes beyond safety requirements: it allows precise packaging optimization in terms of safety, costs and sustainability.

If TechCenter results show that current safety is more than sufficient, we can also perform additional tests to determine the minimum quantity or thickness of material needed to meet requirements. A combination of different packaging methods can also be proposed. To reinforce sustainability, we make our product CO₂ calculator available to you.

This calculates the exact emissions generated by packaging and materials used, offering clues on how to reduce them specifically.

HAZARDS AND LOADS

In our TechCenter we use several test stations to simulate real transport conditions and evaluate load behavior in different scenarios. After completing the tests, we provide you with a certificate with the results.

YOUR ADVANTAGES AT A GLANCE

- Maximum safety, especially in the transport of dangerous goods.

- Cost reduction in primary, secondary and transport packaging.

- Sustainable approach through targeted optimization.

- Adaptation to individual transport routes.

- Test report according to international standards and norms.

- Machinery, materials, tests and optimization all in one supplier.

- Prevention of transport damage and claims.

FOUR TEST STATIONS

The TechCenter is equipped with four dynamic test systems to analyze different stresses on the load and its packaging:

1. Tilt Testing Tool

Tilt test for quick and simple control

In our recommended combination of test methods, the tilt testing tool serves as a simple first indicator for quick quality control through a tilt test. This means we verify whether it travels safely with the previously used transport packaging and whether the load is sufficiently stable and resistant. The results of this method allow quick determination of whether the load unit should undergo additional testing.

2. Horizontal Stability Tester

Simulates accelerations/decelerations following standards (EUMOS 40509, FMCSA)

The Horizontal Stability Tester is a modern and advanced solution for simulating horizontal acceleration and deceleration according to the most important international standards, such as EUMOS 40509 and US FMCSA cargo securement requirements. The driving test shows in real time the effect of predefined horizontal acceleration and deceleration on the stability of your load unit.

3. Inclined Impact Tester

Tests impacts and compression using gravity, reaching up to 2.5 m/s

The inclined impact tester is used to check the protective capacity of transport packaging against impacts and crushing forces during the distribution cycle. Using gravity, the inclined impact tester evaluates the design of transported goods when subjected to horizontal impacts or crushing forces. According to the test protocol, a speed of up to 2.5 m/s is reached.

4. Vertical Vibration System

Generates standard vertical vibrations and random profiles

This device performs standard vertical vibrations and can create random vibration profiles. With our data logger, all real conditions of a distribution cycle can be recorded and reproduced in the vertical vibration system. This allows you to reduce costs from product and packaging damage, or from poor packaging design.

Test your packaging before an incident occurs

We have the necessary tools to perform exactly the crucial tests for your transport route. Load safety is only confirmed when the unexpected happens. We encourage you to take advantage of our technology: schedule an appointment by filling out the form.

We are waiting for you to advise you on the optimal packaging of your loads.