SOLUTIONS FOR PALLETIZED LOAD MOBILITY

MOVITEC, characterized by the manufacture of automatic wrappers, also offers you a wide range of solutions for the mobility of palletized loads, improving the productivity and resources of your company.

Why choose us?

We specialize in offering innovative and customized solutions for load handling, with high-quality equipment that optimizes the performance of your production line.

Contact us today and discover how we can help you improve your end-of-line process.

CONVEYORS

Our conveyors are strong, robust and durable. They are suitable for transporting any palletized load resulting from a wide variety of industrial processes, and are the perfect complement to our wrappers in end-of-line or picking installations.

Benefits of our conveyors:

- Greater efficiency at the end of line, streamlining the shipping process.

- Reduction of operating times and costs, minimizing manual efforts.

- Customizable designs, adapted to the specific needs of each industry.

- Greater safety in load handling, meeting the highest quality standards.

ROLLER CONVEYORS

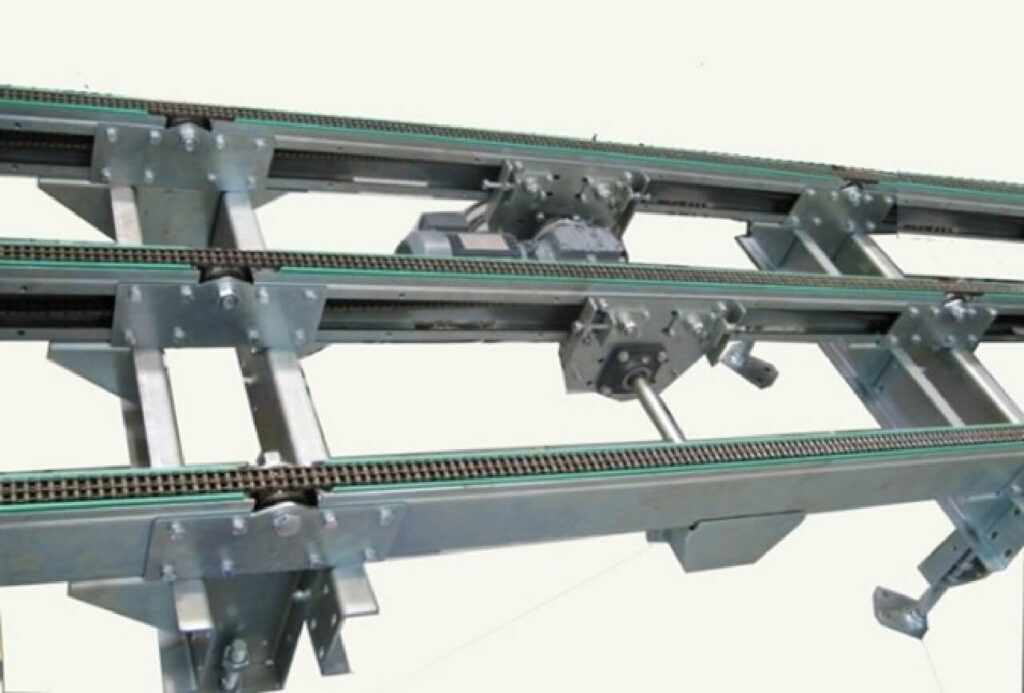

CHAIN CONVEYORS

Specially designed for heavy loads and palletized products. Based on the load to be transported, conveyors can have from 2 to 4 chains.

They stand out for their:

- High resistance and durability, supporting great weights without compromising performance.

- Uniform and safe displacement, minimizing impacts and vibrations.

- Adaptability to different configurations, facilitating integration into automated production lines.

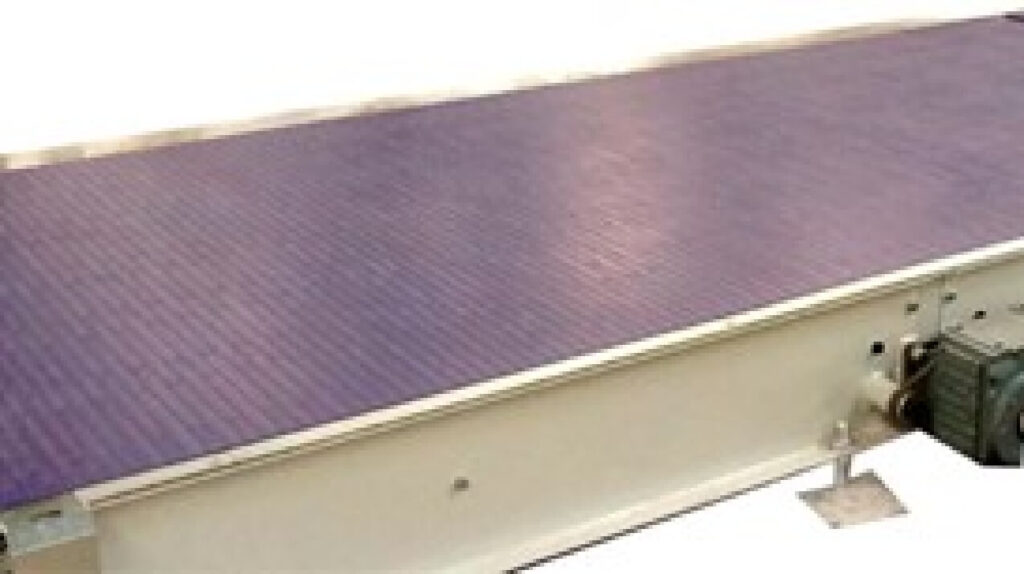

BELT CONVEYORS

Perfect for transporting lightweight products of different shapes, sizes and palletless. They are commonly used in industries where continuous and stable movement is required, such as in the food, pharmaceutical and logistics sectors.

Available in different materials according to application: PVC, rubber, acetal…

ROLLER / CHAIN TRANSFER

The chain-to-roller transfer system (or vice versa) is a mechanism designed to allow efficient transition of loads between different types of conveyors, optimizing material flow within a production or logistics line.

This system is composed of two integrated conveyors:

- Chain conveyor: Ideal for heavy and palletized loads, as it provides stability and resistance in movement.

- Roller conveyor: Perfect for handling boxes, packages and products with rigid bases, allowing agile and precise movement.

- The transfer process is carried out through a lifting mechanism, that activates the elevation of the necessary conveyor to receive or deliver the load.

DOUBLE LEVEL

Two-level conveyors are a highly efficient solution to optimize space and improve productivity in transport systems within industrial plants, warehouses and logistics centers. This system allows the circulation of empty pallets on the lower floor and the circulation of loaded pallets on the upper floor, offering a way to maximize the capacity of available space without compromising process operability.

The two-level conveyor system is designed to separate material flow according to type or state (empty or loaded). This is achieved by providing two independent but interconnected transport lines.

- Lower Level (empty pallets): Empty pallets, previously fed by a pallet dispenser, circulate on this level, ready to be reused or transferred to other areas of the process, such as the storage station or the loading preparation area.

- Upper Level (pallets with product): On the upper level, pallets of products ready for wrapping are transported from the palletizing area. This level is designed to connect to the wrapping area, which requires a constant flow without interference.

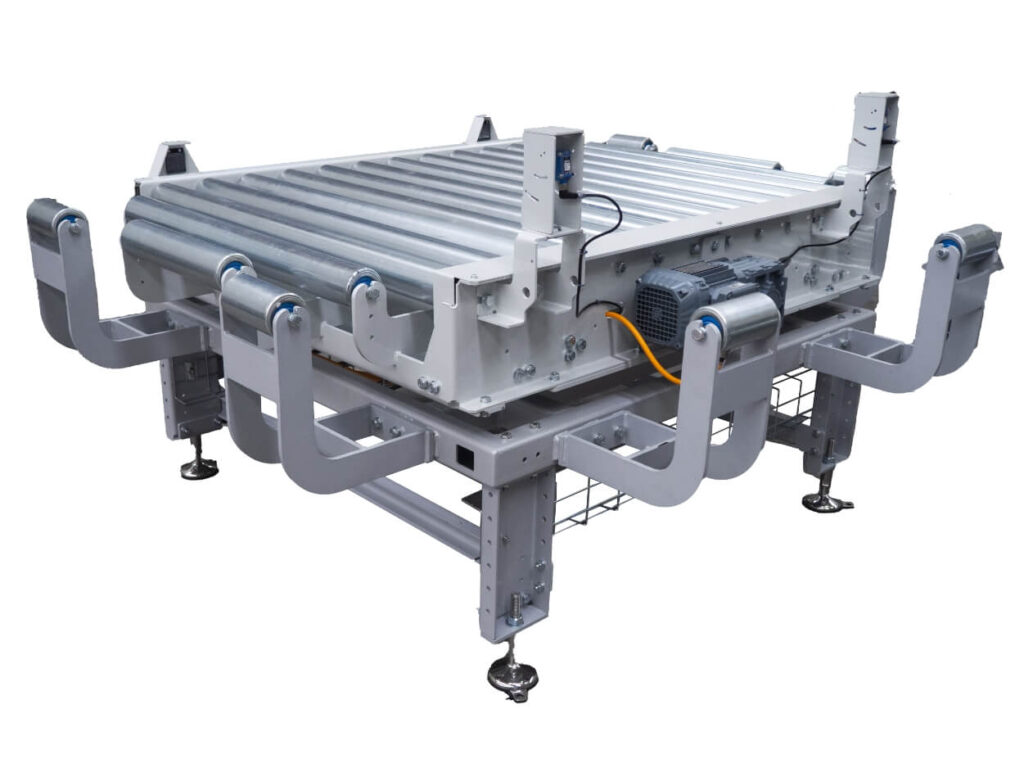

TURNTABLE

Automatic turntables for pallets enable 90º rotation on the pallet’s translation axis.

The turntable can be with roller or chain conveyor.

It is mainly used in end-of-line, logistics centers and industries with automated processes, where it is necessary to redirect products without manual intervention.

System advantages:

- Space optimization, allowing direction changes without the need for large structures.

- Reduction of operating times, improving efficiency in load handling.

- Greater precision in product orientation, facilitating alignment with other conveyors or processes.

- Integration with automated systems, through sensors and programmable controls.

- Improved safety, avoiding manual handling and reducing operational risks.

PALLET INTRODUCTION WITH PALLET TRUCK

Introduction or extraction conveyor designed to facilitate loading and unloading of pallets using a pallet truck. Its optimized design allows an operator to introduce and remove pallets quickly and safely, improving efficiency in warehouses, logistics centers and production lines.

SHUTTLES

TRANSFER

The transfer with motorized base and conveyor (roller, chain, belt) is a system designed to redirect loads automatically within a production or distribution line. It is ideal for direction changes in material flow in end-of-line, storage systems and logistics centers.

This equipment is composed of:

- Motorized base: A mechanism that allows lateral displacement of the conveyor, facilitating the change of product trajectory.

- Conveyor: Roller, chain, or belt system that allows efficient and stable transport of loads on the transfer surface.

- Automated drive: Sensors and controls that activate the transfer movement according to system needs, allowing total integration in industrial automation processes.

- Necessary safety features incorporated to safeguard operators.

elevator

PALLET ELEVATOR

The full pallet is placed on a roller or chain conveyor, and the elevator moves upward to prepare it for handling.

This solution is ideal when working with two different heights of conveyors in the same end-of-line.

PALLET STACKER – DESTACKER

The pallet stacker or destacker is used for the formation of pallet stacks and their storage.

DISPENSER

EMPTY PALLET DISPENSER

Our dispensers have an automatic pallet dispensing warehouse with up and down arms to deliver the pallet onto the conveyor or floor.

ACCESSORIES

Load transportation and handling systems can be optimized through a variety of accessories and complementary devices that improve safety, precision and efficiency in material handling. Below, we present some of the most used accessories in industrial and logistics environments:

BUMPER STOP FOR FORKLIFTS

Support built with robust metal profiles, whose support feet are height adjustable.

WALKWAY FOR OPERATORS

Walkway through the rollers that allows operators to pass.

PALLET CENTERING DEVICE

Composed of two guides that press the pallet laterally to center it to the roller conveyor.

INDUCTIVE DETECTOR FOR FORKLIFTS

Detects the presence of the forklift to prevent motorized roller conveyors from starting. Once the signal is lost, the cycle continues.

ECCENTRIC FOR CONVEYORS

Pallet lifting and loading mechanism to ensure total wrapping of the pallet with plastic film, so that the load is more solidly fixed.

INTEGRATED WEIGHING SYSTEM

Solution that allows the measurement of the weight of products or pallets while moving through the conveyor to enter or exit the area.

PICKCONTAINER

System designed to optimize the collection and distribution of products within logistics centers and warehouses.