From Design to Commissioning

Our end-of-line experience allows us to offer a complete solution, from initial planning to system commissioning and maintenance. We take care of the entire process, ensuring that each component works in perfect synchronization and is aligned with the client’s production objectives.

- Customized design based on client requirements.

- Manufacturing and integration of equipment with existing processes.

- Installation and commissioning with specialized technical assistance.

- Training and after-sales support to ensure maximum performance.

Training and after-sales support to ensure maximum performance. Our approach guarantees an efficient, safe and personalized solution for each industry, optimizing logistics and production processes.

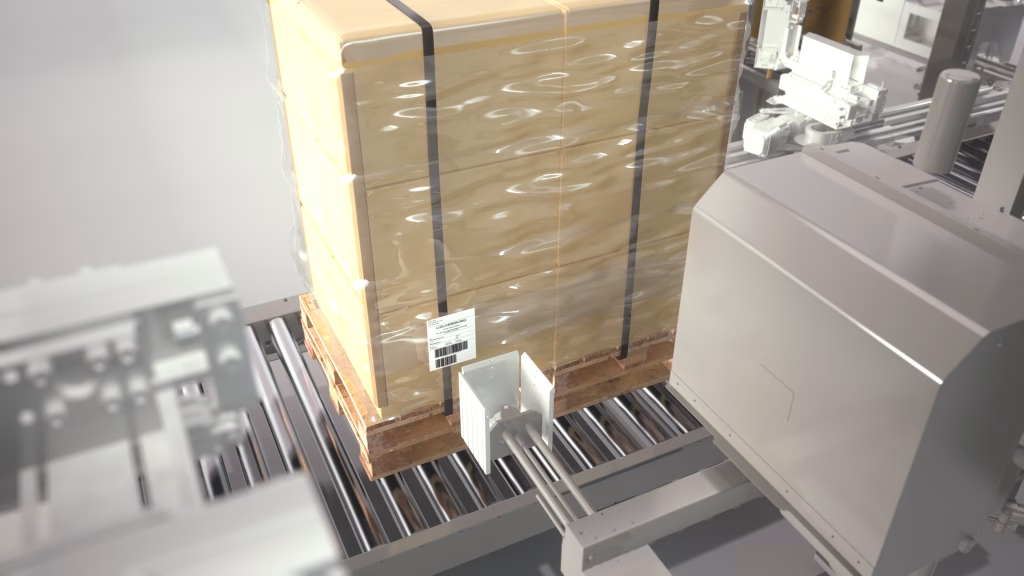

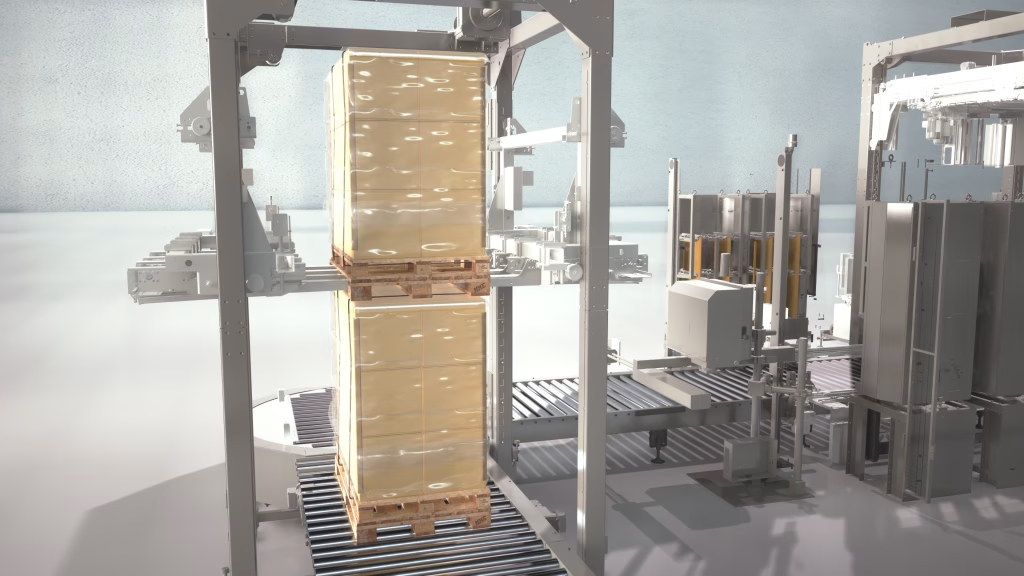

Strapping station

- Automatic wrapping machines with stretch film.

- Strapping machines.

- All safety elements around the installation to protect operators and ensure a safe working environment.

- Top cover to ensure greater product protection against external agents.

- Hold-down plate to guarantee pallet stability and avoid displacement.

- Automatic corner applicator, device that places cardboard reinforcements at pallet corners to improve packaging stability and resistance.

- Automatic reel change to autonomously replace stretch film without manual intervention.

- Customized configurations to ensure load stability and protection.

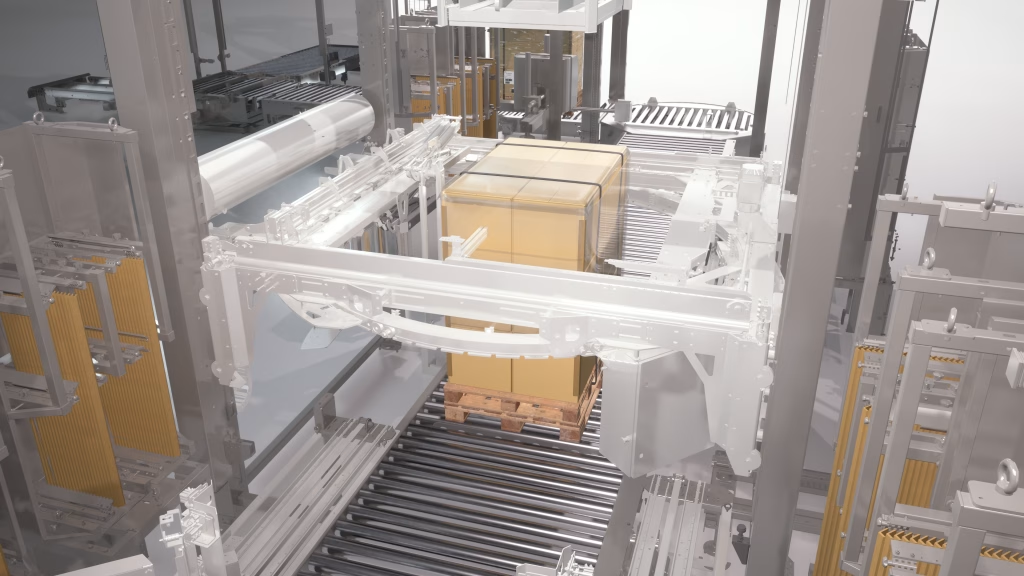

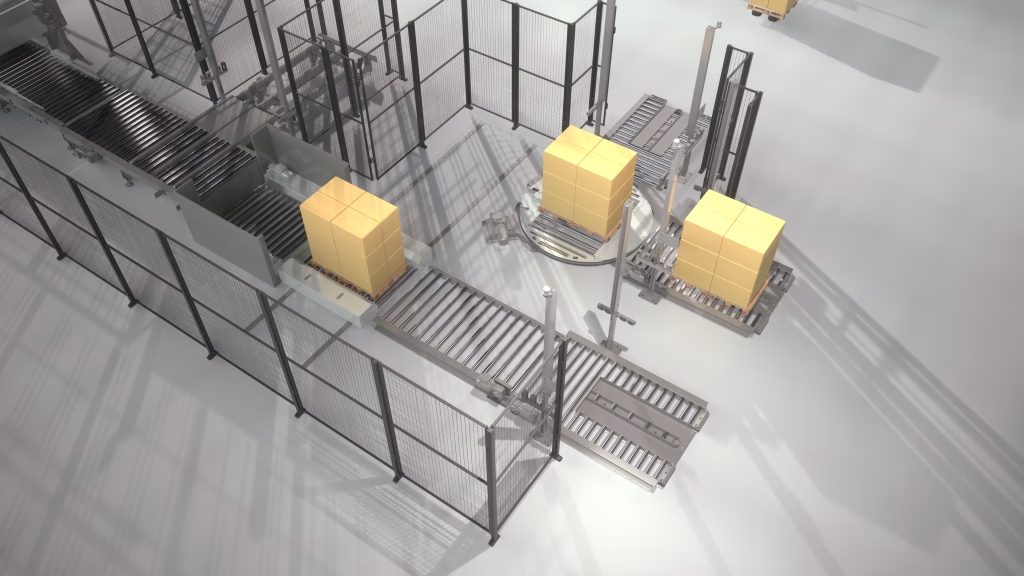

Automated Transport Systems

- Roller, belt or chain conveyors designed to handle different types of loads.

- Transfers, turntables, elevators to optimize product flow.

- Integration with AGVs and automated storage systems.

Complementary Systems

- Stacker / destacker.

- Automatic label applicators for identification and traceability.

- Barcode and QR readers for precise inventory management.

- Weighing system, before or after the wrapping area.

Management and Control Software

- Real-time monitoring systems to optimize performance and reduce errors.

- ERP connectivity for total integration with logistics management.

- Data analysis to improve process efficiency and traceability.

All these elements allow for more efficient, safe and automated operation, optimizing times, reducing errors and improving packaging quality. Contact us to design a customized solution and improve your end-of-line system with the latest technology in automation and safety.